How Analytics is revolutionizing B2B Supply chain around the world

3AI June 7, 2023

Featured Article:

Author: Saswata Kar, Senior Director and Global Head of Data, Analytics & Data Sciences, Philips GBS

This article is about how AI and analytics is really transforming supply chain processes in B2B space.

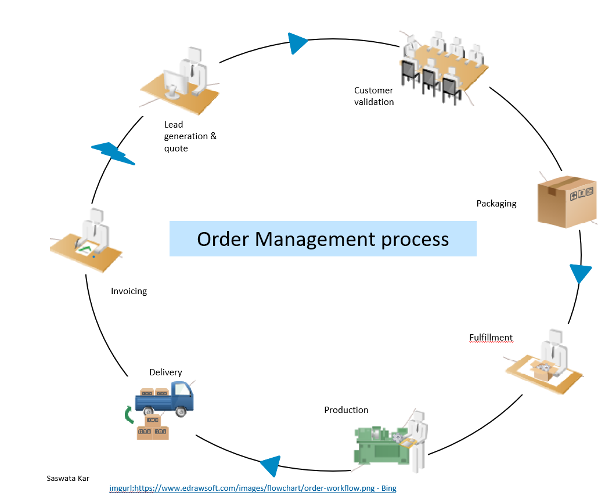

I will be explaining here one use case of Order management analytics, where and how exactly it gets used and how it is bringing in a lot of efficiencies to many organizations at this point in time.

Above diagram is of Order management process that is followed by every organization when they do supply chain. The cycle starts when a salesperson creates or generates a lead, and then the salesperson works with internal organizations to come up with a quote. Next part is validation of customer information and then packaging. Then there is need to get the right vendors followed by fulfillment, which basically stands for how companies ensure that for a particular product, what are the different items that are needed to be assembled. Some items need to be sourced from 3rd party, etc. And then finally it goes for production. Then it goes for delivery to the customers and then the invoicing happens. So the above are some of the very high level process steps that are there in supply chain, any generic order management for any organization. What happens in a lot of traditional organization is really each of these steps are discussed over phone, discussed manually and really people don’t know which step of the process they are and what is the right order. People do the full process by talking and there are inbuilt inefficiencies in not having this big planning. If there is a problem in this chain of activity, then there will be reactive approach to it. For example if there’s a problem with delivery, there will be no knowledge of where it went wrong, whether it was at the fulfillment stage, whether it was at the customer validation stage, so on and so forth. Typically what companies do is a lot of manual tracking. Now where it actually it failed, will not be known. As a result, what happens is, even in supposedly very smooth and very efficient supply chain processes, there are red metrics. Nowadays, some of the big supply chain challenges are due to prolonged lockdown or prolonged warfare. But the origin of bottleneck can be other reasons as well. It is not necessary that it is due to the COVID lockdown. It can be for any other reason in the above chain. Ultimately the customers becomes a little unhappy seeing where they stand and if they don’t get fulfilled (i.e. if they have long waiting time) no customer will be happy in today’s date, when usually a consumer gets things in a matter of weeks.

What does AI and analytics have got to do with the above?

AI and Analytics can influence a lot this order management process. First of all, every step can and should be digitized. That is, digital twin which records the happenings are usually available (in some tool). This is the same as whether an entry has been made of transporting an article or whether a customer got validated. All of it, is done digitally using some digital tool twin.

A lead gets generated online. It will get entered through particular tool in the system of the organization. Some of the tools are really advanced and then a quotation gets generated. All these things are done via digital medium, which means that there’s enough traceability and there’s a single source of truth. So my advice to organizations is always to limit the number of tools that they use. Tools can change, but companies should have one or 2 tools only and they should always be the single source of truth.

We now know at every step where a particular product is, whether it is at a packaging stage, whether it is at a production stage. What happens if traceability is there? We get to calculate how much time is taken on an average per step in Order management, for a particular product type by country or market and so on and so forth. So if we know what is the average time taken for a particular category to a particular country, we know that with this information, we will be able to always predict how much time it will take from one step to another step and if we know how much time it will take, we can always model it right at the invoicing stage. How much time approximately it will take to finish all the 7 steps and hence this provides us with overall approximate time. And then what can happen is if there is a deviation of actual time taken with what the average should have been, there’s an alarm or a trigger or a signal that goes off to the end point. An organization which is informed with such insights can actually go, say (before any work happens) and renegotiate on the deadlines. And the customer will be OK given that they are getting sufficient notice for change in the customer delivery time. And over time, there will be expectations setting, which basically means if earlier the average was 30 day and we consistently see that the average goes to 40 day, then next time when a delivery agent is going, will let the customer know it will take 40 days instead of 30. We can also become better and more efficient in planning, in also predicting where which shipment is stuck or where which item or product is still waiting (for loading) or which vendor is taking longer time. So analytics provides insights on every single aspect of order supply.

Ultimately, all this will result into a metric which is becoming better from red to amber to green probably, and the metrics are really always gets improved upon by algorithms as we get to know the process better as more recent information comes, my data set will always get updated with.

What is the most recent average fulfillment time? What it was 6 months back? All this will result into happy customers. Now it is easier said than done. Because all of this requires a lot of infrastructure, requires a lot of analytics to be done by good analysts. Though the result will speak for itself when this happens.

As written before a better metric results into improved customer satisfaction.

So this is how really analytics is revolutionizing the entire ecosystem of supply chain.

Summarizing, digital twin of the entire process, coupled with single source of truth results in improved metrics. Predictive analytics is also done on how much time it takes from step one to Step 2 to Step 3 as well as depending on which market the sale is being done or which product are we talking about. There will obviously be differences between a large product and a small product, as well as to which country it is getting supplied to.

There can be alerts which will be created at every step, not only by average time, but by some other dimension is also possible. If something is not reaching to the customer validation desk on time, if some vendor is not able to fulfill some of the3rd party supplies, all these risk factors can be predicted Aasuming we are waiting at the point of delivery. In such cases, Analytics team can always let the customers know of the issues or challenges in fulfillment.

The benefits will always be happy customers and great metrics. And finally, what will happen is SCM becomes much more efficient.

Whatever the average was, typically companies get a lot of efficiencies when they implement data technologies in their supply chain. The only caveat is to ensure that organizations use this for driving business benefits and business results (the measurement needs to be tied to value creation for the organization). The data infrastructure, the analytics, they are all means to get to this business result.

Title picture: freepik.com